GRAND RAPIDS, Mich. — (GRBJ) - To make sure its staff is well-trained in a competitive market, supplier company Creston Industrial Sales provided special customized courses through Grand Rapids Community College.

Last August, Creston leaders approached GRCC’s workforce training program to discuss a customized, hands-on class for Creston staff.

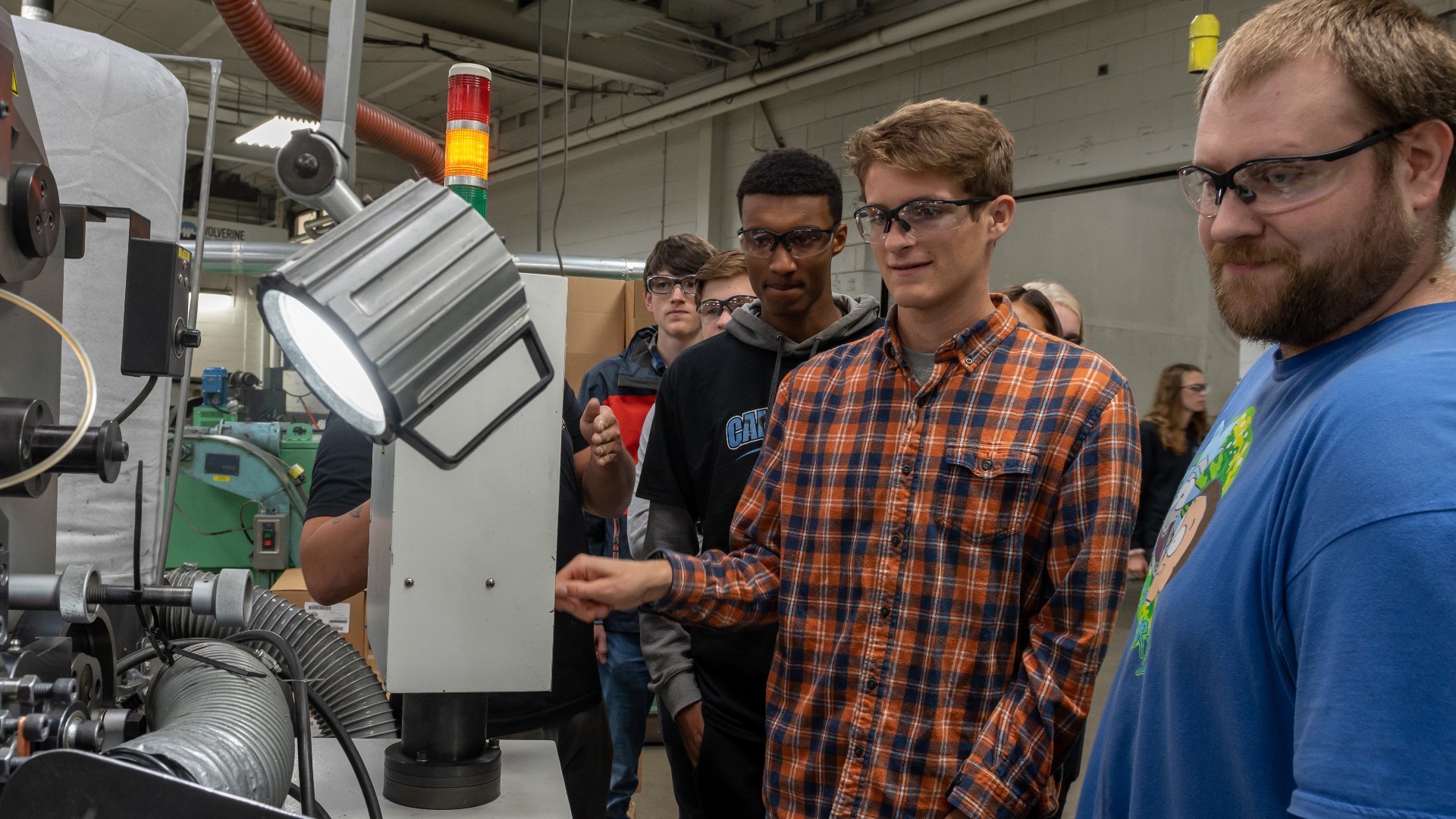

The result is a 32-hour, four-week course to train Creston staff on all the aspects of machining equipment and machine theory.

These classes are meant to help better prepare new and existing workers for the modern field and also give them a broader experience that will be helpful if they choose to advance their careers, said Paul Hendricks, Creston’s president.

With the talent shortage and the need for Creston employees to be knowledgeable in such a specific field, he said the company is pursuing the strategy of hiring salespeople who have experience working with clients and then training them on the specifics of the industry. Historically, he said much of the training would happen on the job.

“Training is a big part of this, but a lot of times that type of training takes years and years, and as we know, there's a shortage of people out there, and there's a high demand,” Hendricks said. “So, what we've been able to do is work with GRCC to come up with our customized training course for our industry with the goal of shortening the timeframe that it takes to do this.”

David Darling, Creston COO, had the idea of working with GRCC and was in charge of putting the collaboration together.

Three new employees and five existing employees took the first course, Hendricks said. With the training courses completed, the three new employees are being matched with experienced application engineers who can help solve complicated problems for clients.

With investment by the employer, GRCC can customize classes for any business in any industry, said Mary Hofstra, the corporate customized training manager.

The program has served more than 5,000 employees and at more than 345 companies, including Meijer, Lacks Enterprises, DeWys Manufacturing and Zeeland Lumber & Supply.

The classes typically are noncredit and can be any number of hours.

After consulting with the company, Hofstra said courses are tailored based on what is needed and either uses a GRCC instructor or contracts one from outside the college.

Creston’s classes took place in the new AMP Lab at WMU in downtown Grand Rapids. Hofstra said having access to venues like this is beneficial to companies for training purposes because if something goes wrong with the machines during the learning process, the companies don’t lose money as they would in their own manufacturing plants.

In his business, Hendricks said workers need to do more than just supply a product because there are vast options on where to buy different products.

“We need to be a solutions provider,” Hendricks said. “In effect, we need to go and help find the best products in the world for that particular application for our customers.”

That’s why it’s important that his workers are educated on how to deliver the best solutions they can for clients, Hendricks said.

“It can be the difference for (clients) sometimes between making money on a job and not making money on a job.”

He said customers are relying on the expertise of suppliers more and more, so he wants to make sure his employees are able to do that.

He said the company is working on improving other areas, as well, such as by visiting other companies to learn how they deal with logistics and learning how to train people on how technology is changing.

It’s all about trying to ensure the company is “ahead of the curve,” Hendricks said.

This story originally appeared in the Grand Rapids Business Journal. To find a similar content, pick up a copy or find more on their website.

Other GRBJ stories featured on 13 ON YOUR SIDE:

RELATED VIDEO:

►Make it easy to keep up to date with more stories like this. Download the 13 ON YOUR SIDE app now.

Have a news tip? Email news@13onyourside.com, visit our Facebook page or Twitter. Subscribe to our YouTube channel.