NORTON SHORES, Mich. — Muskegon, Michigan is on Mars!

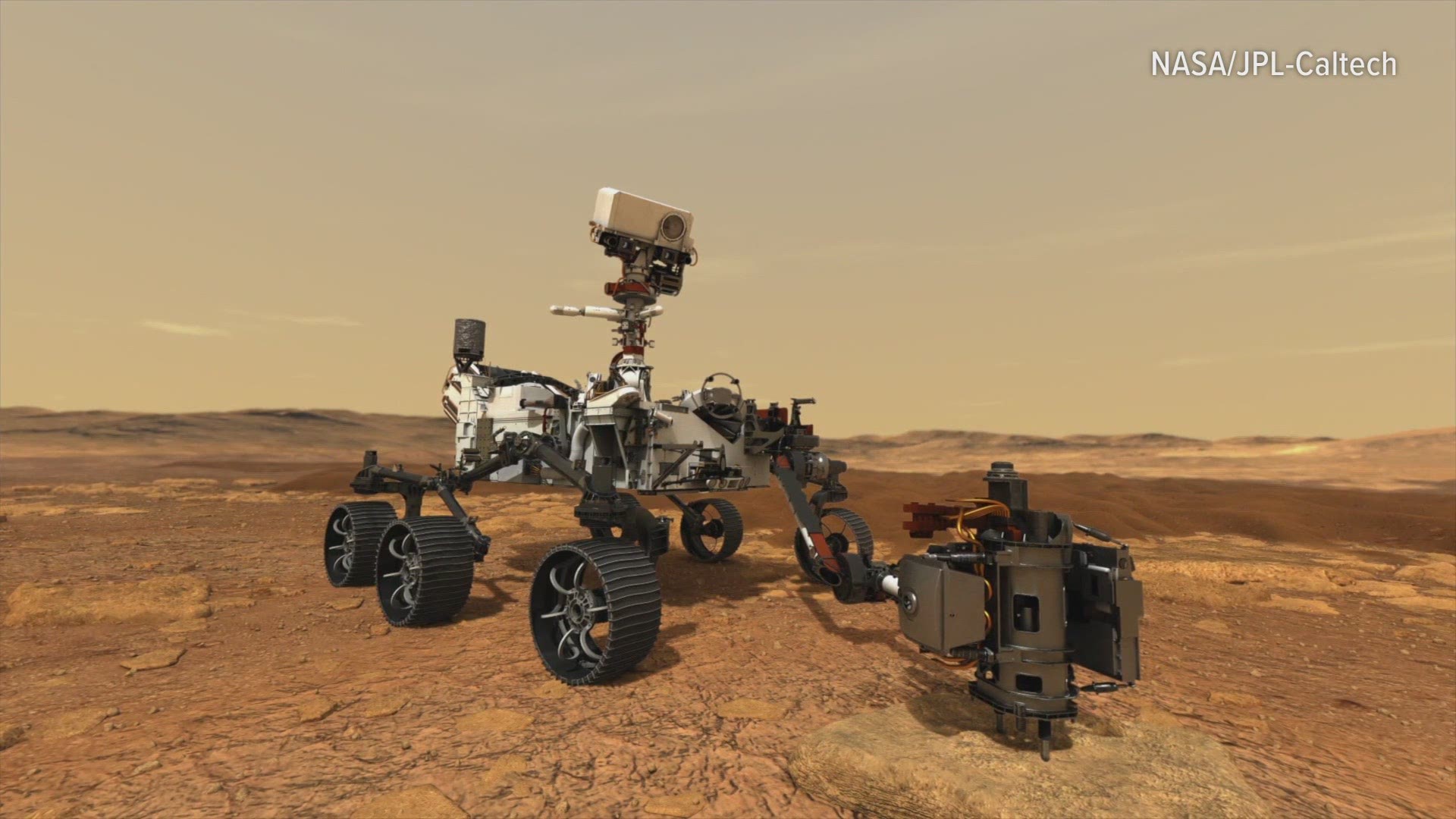

It's the truth, because each time NASA's Perseverance Mars Rover collects and handles rock and regolith samples during its multi-year mission, critical components designed by SKF Kaydon Corporation in Norton Shores, Mich., enable the robot to accomplish its core operations on the surface of the red planet.

"It's great to be a part of this," said Joe Zagar, who's in his 38th year as a product development engineer at SKF Kaydon. "And to think the original design that was created so long ago is still wanted and needed today, is amazing."

In the 1950s, without the aid of computers, Kaydon engineers developed the RealiSlim thin-section ball bearings which have been used by NASA for the past 40 years.

The special application bearings have been featured on the following previous missions:

- 2004 and 2012 'Curiosity' and 'Spirit' Mars Rovers.

- Space Shuttle Columbia in 1981 and the International Space Station.

- Hubble Space Telescope, as well as various satellites.

"Our precision thin-section bearing is exactly what they need in space," said Zagar.

Zagar says the Norton Shores corporation was contacted in 2018 about needing the special bearings, which were then manufactured at SKF's hub in Sumter, South Carolina.

"At the time, we were told they'd be for 'The Mars 2020 Project,'" said Zagar. "NASA wanted five different bearings."

That project, of course, became the Perseverance Mars Rover expedition.

"There's no such thing as other technology that can totally replace our bearing design," added Zagar. "What was designed 70-plus years ago still solves a lot of problems for NASA."

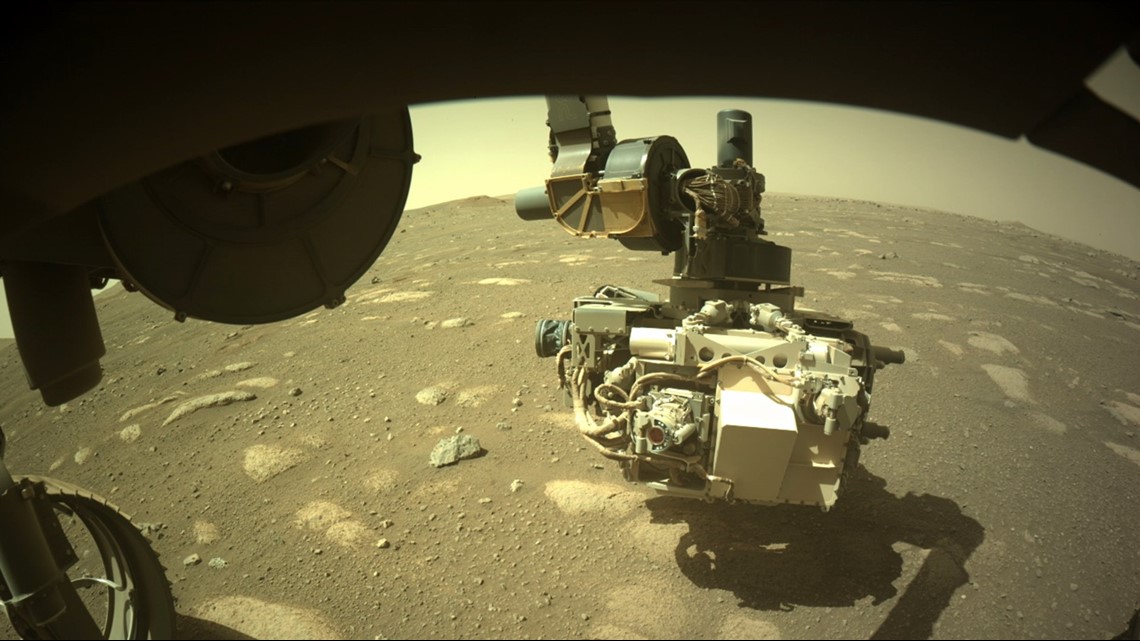

The highly engineered components contribute to the survival of the Rover's main robotic arm, sample collecting turret, tool bit carousel and sample handing assembly during the months-long trip it endured through space, and its function as intended on the Mars surface.

'It's helps in the handling of the rocks and when the Rover excavates," said Zagar. "The bearings allow for 'spot analysis,' which is the ability to examine all the collected samples much more closely."

When the Rover is ready to begin collecting samples on the surface, the robotic arm will maneuver into place and the tool bit carousel will whirr into action, deploying tools to drill or abrade material. Which will then be collected by the sample collecting turret and transferred to the sample handling assembly for processing on board the Rover, and eventually a potential return to Earth for analysis via a future Mars mission.

"Without our bearings, the Rover vehicle would probably still have been sent to Mars to run around on the surface and do what it's doing, but NASA wouldn't be able to really receive back as much detail as what they can get today," added Zagar. "As I watch the news coverage, I'm proud of the fact that without Muskegon's engineering design, that's stood the test of time for more than a half-century later, the work being done by the Rover would still be important, but not as thorough."

Zagar says that SKF Kaydon has also designed integral components for Elon Musk's SpaceX Program, though he couldn't say what those specific parts were.

RELATED VIDEO:

►Make it easy to keep up to date with more stories like this. Download the 13 ON YOUR SIDE app now.

Have a news tip? Email news@13onyourside.com, visit our Facebook page or Twitter. Subscribe to our YouTube channel.