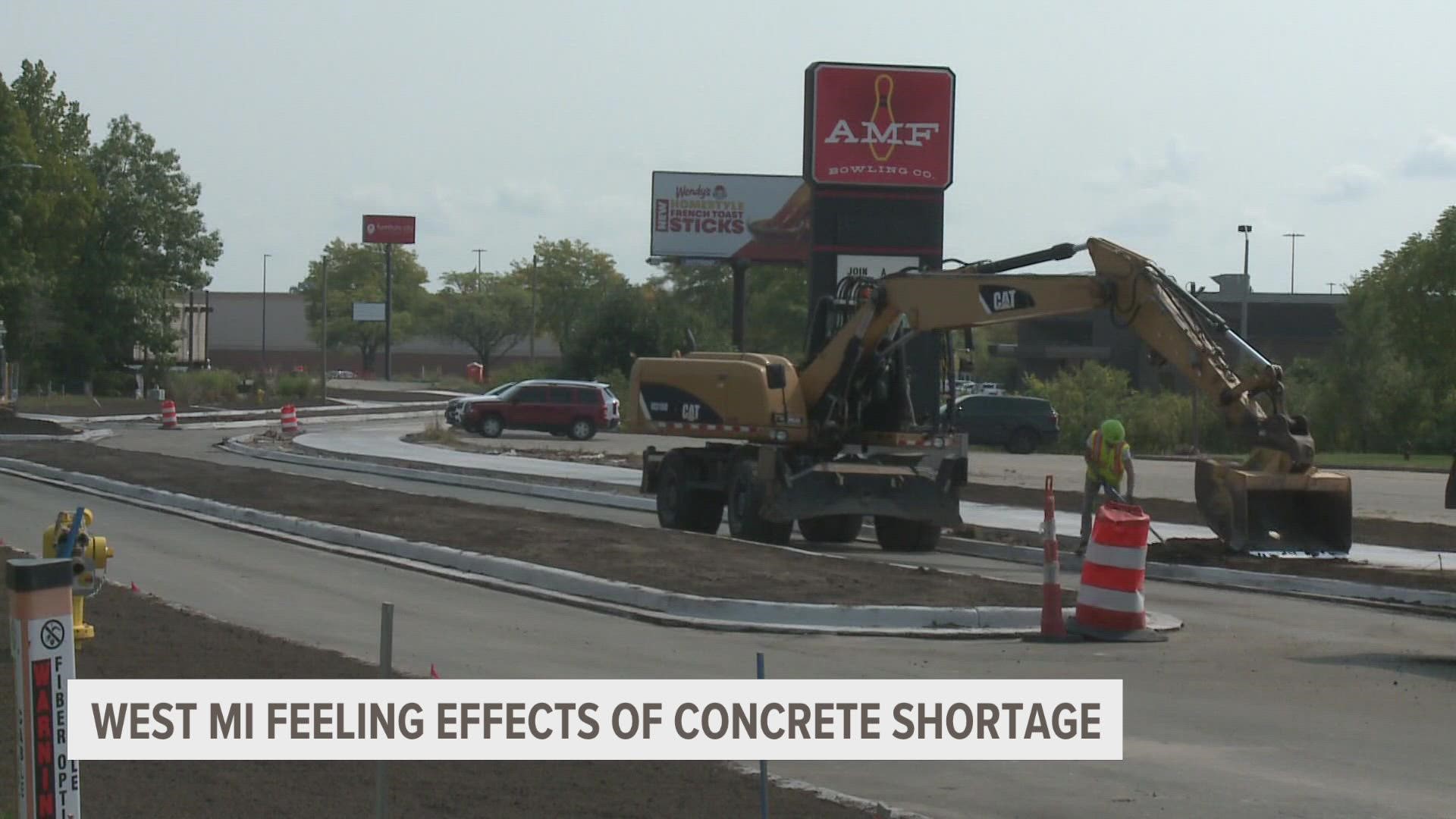

MUSKEGON, Mich. — From the roads you drive, to your home and your office, to the bridges, runways and parking lots that keep the country moving, concrete is among the most ubiquitous building materials on Earth.

In 2022, however, concrete has become increasingly difficult to find.

That’s the reality after the industry saw a demand surge in May.

“The weather has been phenomenal in Michigan this summer,” Dan DeGraaf said. “It's been hot and dry and people have been working seven days a week.”

DeGraaf heads the Michigan Concrete Association, the trade organization representing many among the state’s stable of cement suppliers, contractors, construction firms and engineers.

“We've been working on a lot of projects,” he noted.

This has proven an issue because of a cement supply chain that relies on filling regional storage terminals during the slower months and keeping them filled with additional production throughout the year.

“Basically, we ran the terminals out of cement,” DeGraaf explained. “So, we're only getting what is direct feed from the plants right now. So, it's not fast enough to meet what people want on a day-to-day basis.

In addition to producing much of its own concrete, Michigan imports the material from several surrounding states, much of which is transported to and from cement factories via either rail or over the Great Lakes.

As a result of the present shortage, DeGraaf said suppliers had begun to prioritize certain projects over others in a push to curb potential delays where they’d be felt most acutely.

“People are seriously trying to pay attention to who gets the cement a bit,” he said. “Each producer now has an allocation that he gets and he's got to make a decision on a daily basis.”

“We're trying to prioritize what we can do,” Dave Weurding, who co-owns the Mitten Concrete in Marne, explained. “Existing jobs that we have open right now, open holes in the ground that we've got to get stuff in so that people can wrap up projects.”

As the inevitable winter slowdown loomed, shortages meant his crews were reduced to only pouring around four days a week, instead of the six they averaged earlier this year.

Mitten, Weurding said, had been insulated from the worst of it until recently.

“As of three weeks ago, it's really tightened up,” he said. “It's affected us quite a bit.”

Weurding asked clients to remain patient as they worked through the issues.

Delays may mean a handful of projects will have to wait until spring, he said. The hope is that the crunch will have been resolved by that point.

“That’s always the big question,” DeGraaf said. “If the housing market slows down… the outlook should be okay next year… there’s so many factors that impact that, we can’t make a guarantee either way.”

An MDOT spokesperson told 13 ON YOUR SIDE that, to date, none of its major projects had been affected by the supply shortage.

It’s harder to determine whether that’s the case for local projects, and if so, to what extent.

►Make it easy to keep up to date with more stories like this. Download the 13 ON YOUR SIDE app now.

Have a news tip? Email news@13onyourside.com, visit our Facebook page or Twitter. Subscribe to our YouTube channel.